Evaluating Refrigerant Levels

Refrigerant levels play a critical role in the performance of a refrigeration system. An insufficient amount can lead to inefficiency, while an overcharged system may result in compressor damage. Regular monitoring and evaluation of refrigerant levels ensure the system operates at optimal efficiency. Technicians often use specialized gauges to measure pressures and determine whether the refrigerant charge is within acceptable limits. This evaluation is crucial not just for troubleshooting issues but also for maintaining the system throughout its lifespan.

When diagnosing a refrigeration system, understanding the refrigerant type and its specific characteristics is vital. Different refrigerants have unique pressure-temperature relationships that need to be considered during the analysis. In the context of refrigeration system installation and repair, attention to refrigerant levels can prevent future complications. Accurate assessment can guide necessary adjustments, ensuring the system functions effectively and reduces the risk of costly repairs due to neglect.

Techniques for Assessing Refrigerant Charge

Assessing refrigerant charge is crucial for ensuring the efficiency of a refrigeration system. Technicians often use pressure gauges to measure the system's operating pressures. By cross-referencing these pressures with manufacturer specifications and ambient temperatures, technicians can determine whether the refrigerant level is appropriate. Additionally, superheat and subcooling measurements provide deeper insights into the system's performance, helping identify potential issues that may require attention during refrigeration system installation and repair.

Another widely used method is the visual inspection of the refrigerant lines. Observing for signs of leaks, frost buildup, or discoloration can indicate problems with refrigerant levels. Infrared thermometers can also assist in checking temperature differentials across the evaporator and condenser coils. Together, these techniques facilitate a comprehensive assessment of the refrigerant charge, ensuring optimal functionality and longevity of the refrigeration system.

Inspecting Electrical Components

Inspecting electrical components in a refrigeration system is crucial for ensuring its efficient operation. The electrical system includes various elements such as relays, fuses, and thermostats, all of which play vital roles in the function of the unit. A thorough inspection involves checking for signs of wear or damage to wiring and connections. Loose or corroded connections can lead to system failures or inefficiencies that may require refrigeration system installation and repair to resolve.

Identifying common electrical failures is essential in diagnosing refrigeration issues. Problems like blown fuses, malfunctioning thermostats, or faulty compressors can impede the system's performance. Regular maintenance and inspections help catch these issues early, preventing costly repairs or increased energy consumption. By ensuring that electrical components are functioning correctly, technicians can maintain optimal performance levels and prolong the life of the refrigeration system.

Identifying Common Electrical Failures

Common electrical failures can often impede the efficient operation of a refrigeration system. One prevalent issue is the malfunction of the compressor relay, which is crucial for regulating the power supply to the compressor. When this component fails, the compressor may not start or could run continuously, leading to energy waste and potential damage to the system. Additionally, problems with the wiring connections can arise, especially in older systems, where frayed or damaged wires may cause short circuits or intermittent power loss.

Another frequent electrical concern involves the overload protector, designed to safeguard the compressor from overheating. If this device fails, it may not trip in response to dangerous temperature levels, risking severe damage to the compressor. During diagnosis, it is essential to check all electrical components, as issues often correlate with the age and condition of the refrigeration system. Proper inspection and understanding of these common failures are integral to effective refrigeration system installation and repair.

Analyzing Airflow and Ventilation

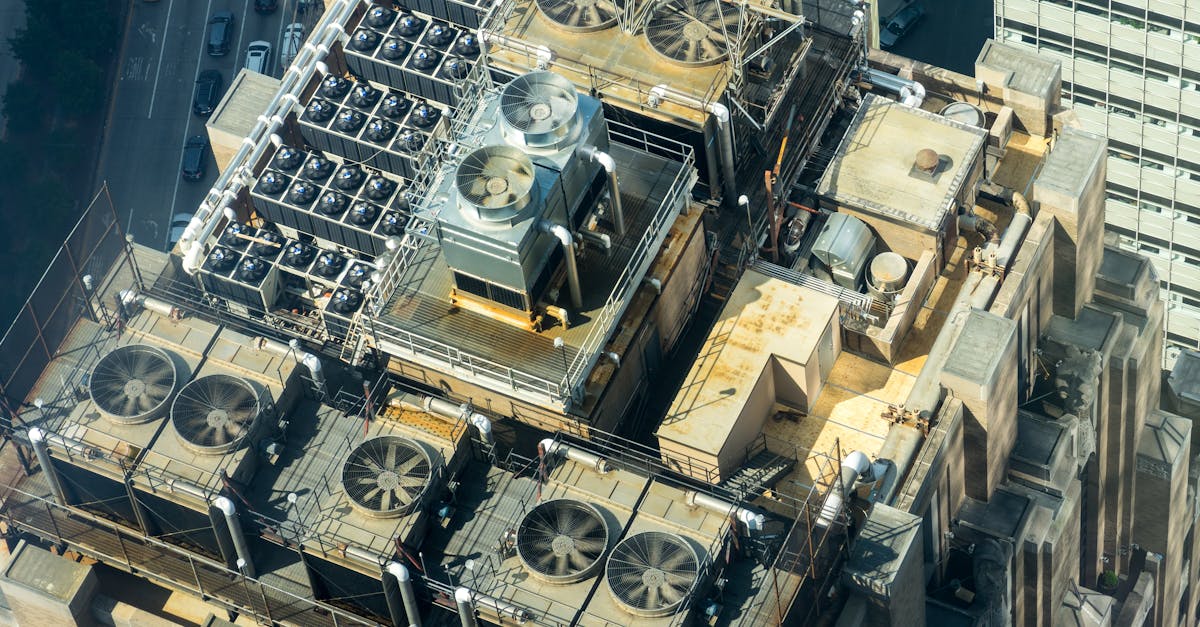

Proper airflow and ventilation play crucial roles in the efficiency of a refrigeration system. Insufficient airflow can lead to inconsistent cooling temperatures, increased energy consumption, and potential damage to the unit. To assess airflow, technicians often examine air filters, ducts, and any obstructions around the unit. This process is vital for ensuring that cold air circulates effectively throughout the designated area, which in turn helps maintain optimal operating conditions.

During refrigeration system installation and repair, attention must be given to the design and placement of vents and fans. An effective layout prevents hot spots and allows for even distribution of cool air. Furthermore, technicians should routinely check for fan operation and duct leaks. Addressing these issues not only enhances performance but also prolongs the lifespan of the equipment, making it an essential step in maintaining a reliable refrigeration system.

Importance of Proper Airflow in Refrigeration

Proper airflow is crucial for the efficient operation of any refrigeration system. It directly impacts the system's ability to maintain the desired temperature and to operate at peak efficiency. When airflow is restricted due to blockages or improper ductwork, the compressor works harder, leading to increased energy consumption and potential overheating. This not only reduces the lifespan of the system but also results in higher utility bills.

In the context of refrigeration system installation and repair, ensuring that the airflow is optimized can make a significant difference in performance. Technicians must assess the layout and condition of air ducts and vents as part of routine maintenance and repairs. Regular checks can help identify issues like dust buildup or fan malfunctions that impede airflow, thereby enhancing the overall effectiveness and reliability of the refrigeration system.

FAQS

What are the first steps in diagnosing a refrigeration system?

The first steps typically involve evaluating refrigerant levels, inspecting electrical components, and analyzing airflow and ventilation to identify potential issues.

How can I check the refrigerant levels in my refrigeration system?

You can check refrigerant levels by using pressure gauges to assess the system's pressure readings and ensure they are within the manufacturer's specifications.

What electrical components should I inspect when diagnosing a refrigeration system?

It's important to inspect components such as the compressor, relays, capacitors, and wiring for signs of wear or failure.

Why is airflow important in refrigeration systems?

Proper airflow is crucial as it helps in efficient heat exchange, maintaining the desired temperature, and preventing overworking of the system components.

What common electrical failures should I look for in a refrigeration system?

Common electrical failures include burnt out compressors, faulty relays, damaged wiring, and malfunctioning thermostats, which can all disrupt system performance.